精于专——专业销售水泥罐水泥仓厂家

水泥罐生产销售一体化,多年技术人员,成熟生产设备 优质产品

优质产品水泥搅拌罐经久耐用,众多客户验证

厂家实力

厂家实力散装水泥罐厂家直销,实时询价

产品资历

产品资历专注品质,证书齐全

贴心服务

贴心服务水泥罐多年技术人员跟踪服务

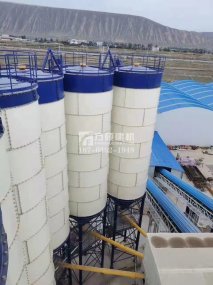

郑州方硕机械设备有限公司始建于2000年,是集建筑机械的整机及零配件开发、制造、销售为一体的专业化公司。地址位于机械之乡的河南省荥阳市工业园区。多年来立足客户要求,致力科技创新,在行业内快速崛起。 由于地理位置得天独厚,朋友和用户的鼎立支持,我公司近几年发展迅速,产品和口碑在行业内获得好评,产品远销哈萨克斯坦、俄罗斯、土耳其、印度尼西亚、缅甸、越南、埃塞俄比亚、等国家,用户分布全国各地。本厂专业销售水泥罐、散装水泥罐、立式水泥罐、卧式水泥仓、片式水泥仓等水泥罐设备。 我公司拥有完整、科学的质量管理体系,完善的售后服务队伍。公司全体员工严格按照ISO9001:2000的要求,并以完善的管理,完善的服务,完善的产品,完善的质量为宗旨.为您提供优质的产品和服务,欢迎各界朋友莅临参观、指导和业务洽谈。 郑州方硕机械设备厂家全体同仁始终坚持科技与品质同行。以质优、价廉、服务的经营方针。以重合同、守信誉的经营原则。以团结、开拓、创新 ...

查看更多+新闻动态

2023-01-12水泥罐保养要求你做到了几点?

混凝土搅拌站中的 水泥罐 一般用来储存散装水泥、粉煤灰等建筑材料。 散装水泥罐 适用于工业建筑城市建设,道路桥梁水...常见问题